Electroglobal SA implemented this project as requested through a construction materials company.

Project Objective

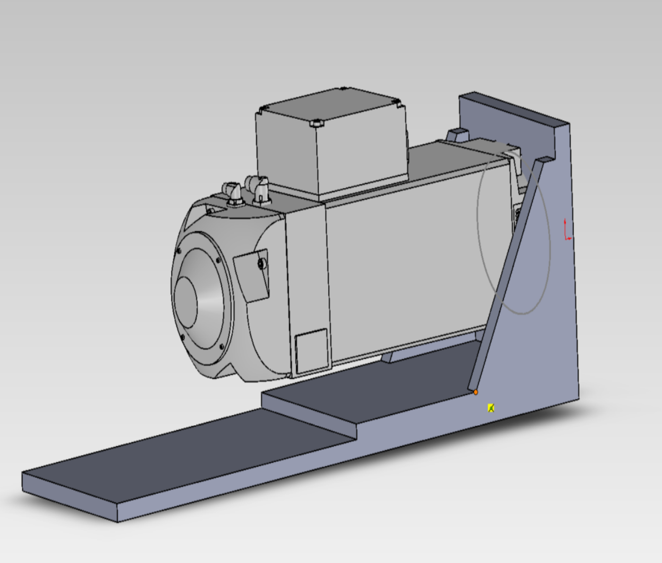

The purpose of this project was to replace an outdated drive system with a Siemens Sinamics G130 converter system, including protection & switching and automation systems, to meet higher process demands while preventing overload.

The automation system efficiently and automatically manages three converters that control two motors. Two of the converters operate in parallel to power the motors, while the third remains in standby. In the event of a failure or maintenance operation on one of the main converters, the standby converter activates to ensure continuous motor operation.

The system is designed so that switching between converters is only possible in Local mode via the HMI interface and only when all VFDs are stopped, as per a software interlock. Additionally, the system retains the last used configuration, ensuring that settings are automatically restored upon power restoration.

Project Description

The automation system utilizes a set of switches and disconnectors that allow any two converters to operate the two motors, ensuring their power supply from a transformer with a 6kV primary and two 0.4kV secondaries. The selection of converters is only possible if disconnectors C1-C8 are in the correct configuration, as specified in the project’s reference table.

The frequency converters are interfaced with the HMI system (TP1200 Comfort model) via a Siemens S7-1200 programmable logic controller (PLC), model CPU 1214C DC/DC/RLY. This PLC is responsible for monitoring the converters’ parameters and implementing the control logic necessary to ensure the system operates under optimal conditions.

Equipment Used

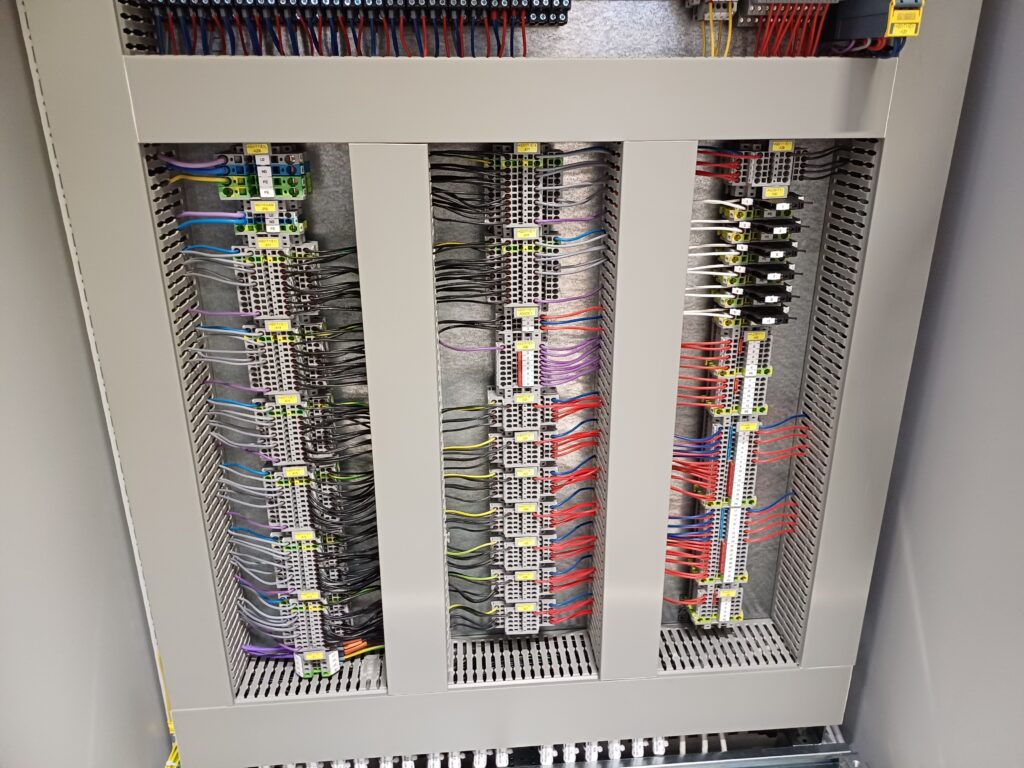

Automation Panel:

- PLC: Siemens S7-1200

- HMI: TP1200 Comfort

- The PLC communicates with the VFDs (converters) via PROFINET.

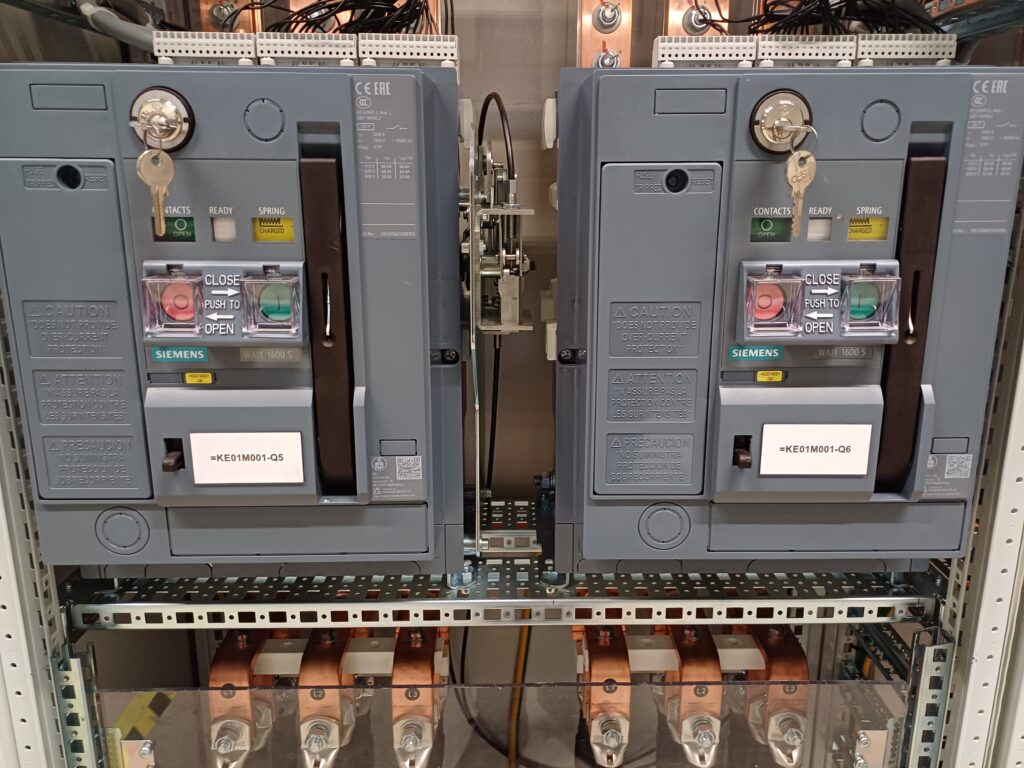

Protection and Switching Panel:

- VFDs: Sinamics G130 power module with CU320-2 DP control unit

- Input Circuit Breakers: 3WA fixed-mounted, motorized, 1600A – Siemens

- Output Disconnectors: 3WA fixed-mounted, 1600A – Siemens

- Busbar System: MAXI-PLS 1600A – Rittal

Benefits

- Replacement with Higher-Power Converters

Ensures increased capacity to meet higher process demands, preventing overload and extending equipment lifespan.

- Elimination of Failure Risks in Existing Converters

Replacing converters nearing the end of their service life reduces the risk of malfunctions and unplanned downtime, ensuring a more reliable system.

- Improved Operability and Reduced Downtime

The automated switching system replaces the manual process, significantly reducing downtime and increasing operational efficiency.

- Prevention of Cable Damage

Eliminating repeated cable handling prevents wear and tear, reducing failure risks and maintenance costs.

- Optimized Monitoring and Control via HMI

The TP1200 Comfort HMI and S7-1200 PLC enable precise monitoring of converter parameters and more efficient drive system management.

- Enhanced Safety and Reliability

The modernization improves system safety and reliability, ensuring continuous and stable operation of the two fans, thereby reducing operational risks.