This project was requested for a client in the railway industry with extensive experience for its staff in the production, maintenance, and refurbishment of freight wagons.

Project goal:

The complete replacement of the electrical control and command panels with equivalent ones for the automatic sandblasting machine in the painting area.

Project description:

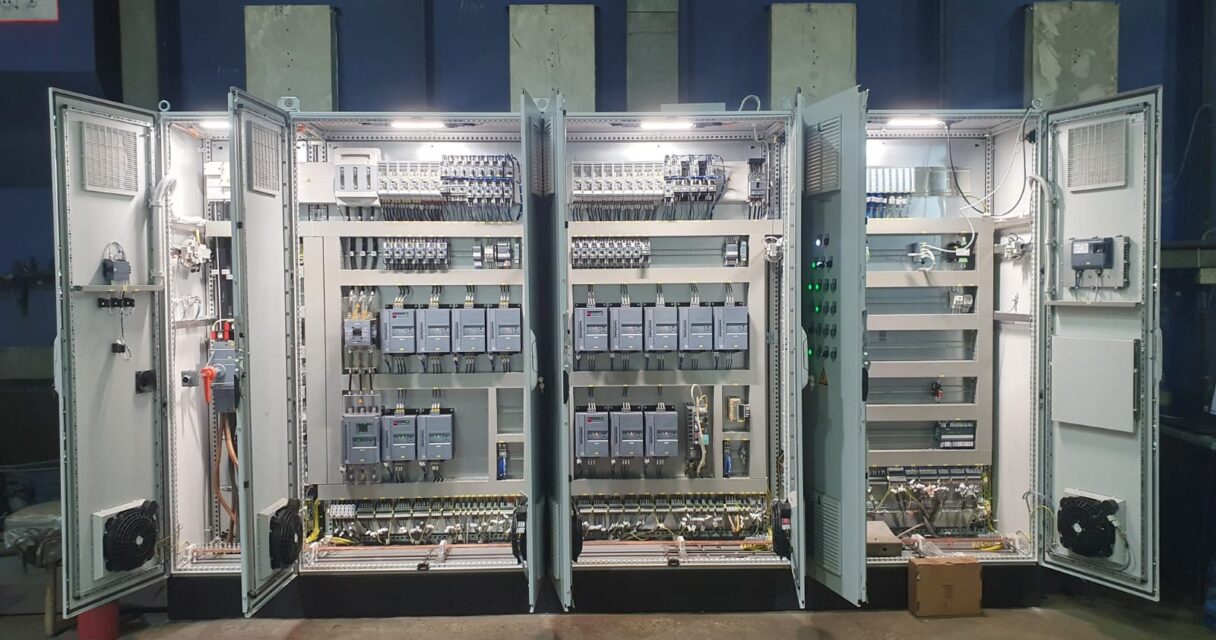

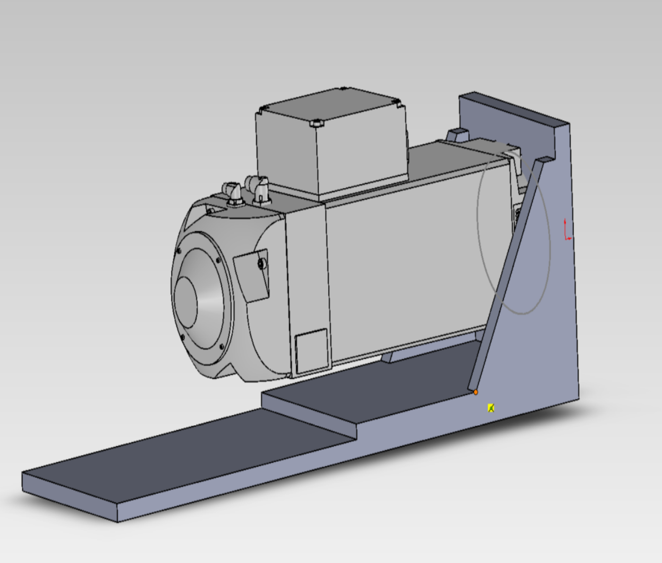

Electroglobal SA designed an automation panel for the automatic sandblasting line of a wagon, which controls approximately 25 motors of various power ratings, as follows:

- 2 motors of 0.55 kW

- 1 motor of 1.1 kW

- 1 motor of 4 kW

- 4 motors of 5.5 kW

- 10 motors of 10 kW

- 4 motors of 30 kW

- 1 motor of 90 kW

Control type:

Most motors are controlled via ON/OFF switching, while the 4 kW motor is controlled via VFD.

Control system upgrade:

The initial S7-300 PLC system was replaced with an S7-1500 PLC system to improve performance and reliability.

Operator interface:

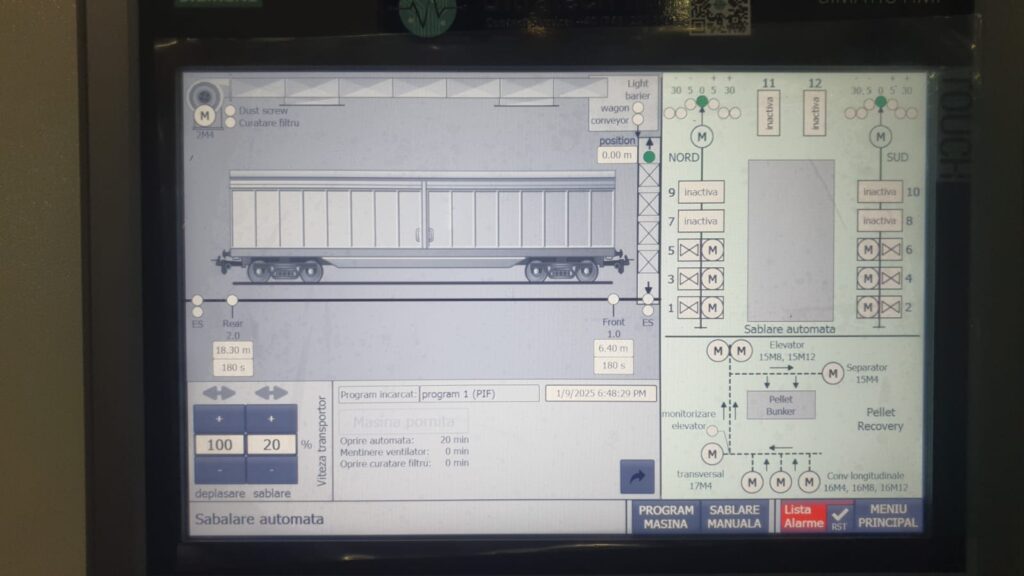

The panel is equipped with a Siemens SIMATIC HMI TP1200 COMFORT Touch Panel for intuitive system control and monitoring.

Used equipment:

- Metal enclosure VX range, manufacturer Rittal

- Switchgear 3RT, 3RV, manufacturer Siemens

- PLC S7-1500 range with CPU 1511

- Soft starter 3RW52, 3RW55 200-480 V range, manufacturer Siemens

- VFD G120 PM240-2 range, manufacturer Siemens

- Busbar distribution system PLS800A, manufacturer Rittal

Project benefits:

The modernization project of the automatic sandblasting line for wagons included the implementation of an automation panel with advanced solutions for improved efficiency and control. The main benefits include:

- Integration of ammeters for the 12 turbines directly into the PLC system, with visualization on the HMI for simplified monitoring.

- Integration of the WEST 8000 temperature controller into the PLC for precise process management.

- Use of Softstarter for starting the 90 kW fan and the 4 x 30 kW and 8 x 15 kW turbines, replacing the classic Y/D method, for smoother startup and reduced equipment wear.

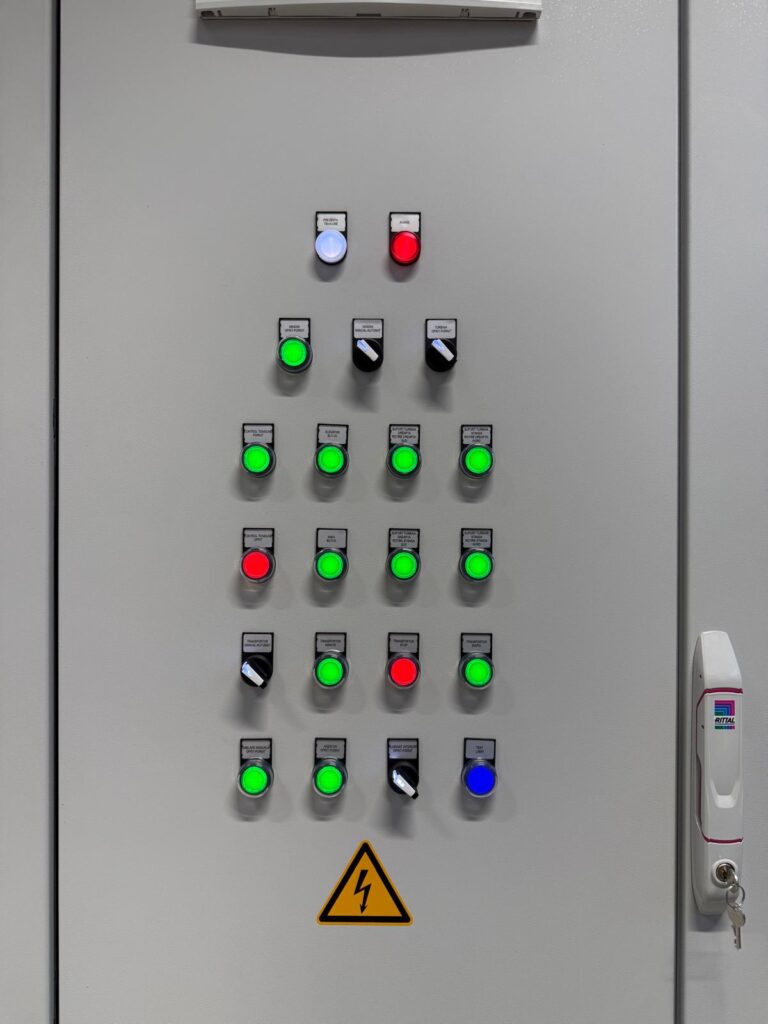

- Control remains flexible, both through the buttons and selectors on the panel door and through the HMI interface, ensuring easy and accessible management.

These improvements have led to more efficient and reliable operation of the line, contributing to increased performance and reduced risks.